By: Jake

After a successful run for a trophy finish at the 2010 SCCA Solo National Championship in Super Street Modified Class, the Hamfist Racing RX7 experienced a devastating blow to its progress and development. A combination of over-boosting, over-revving, maxing out fuel system capacity, and suspect octane levels, led to a not-so-unprecedented apex seal failure. The long trailer ride to Speed1Allentown was the start of a comprehensive, yet premature, powertrain overhaul that would bring the car into the pinnacle of Super Street Modified competition.

By: Jake

After a successful run for a trophy finish at the 2010 SCCA Solo National Championship in Super Street Modified Class, the Hamfist Racing RX7 experienced a devastating blow to its progress and development. A combination of over-boosting, over-revving, maxing out fuel system capacity, and suspect octane levels, led to a not-so-unprecedented apex seal failure. The long trailer ride to Speed1Allentown was the start of a comprehensive, yet premature, powertrain overhaul that would bring the car into the pinnacle of Super Street Modified competition.

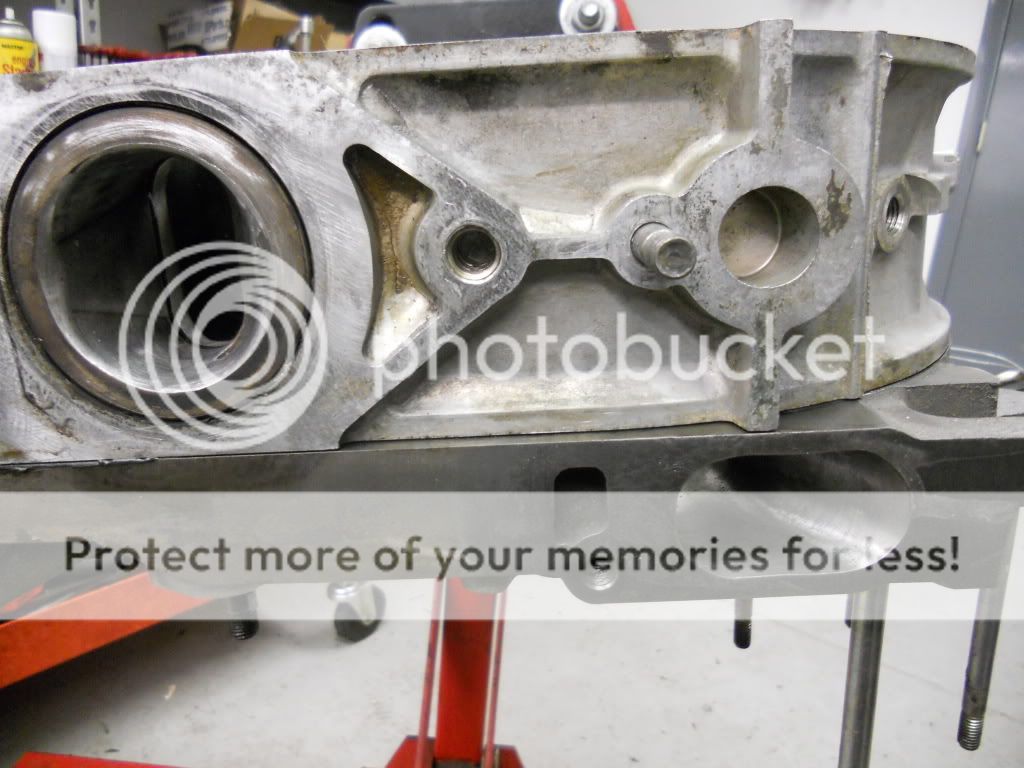

Speed1Allentown, aka KDR Performance, began the tear down and port polishiing – intake & exhaust – of the 13B rotary engine. Before the engine could be put back together, the entire rotating assembly, including a pair of new high compression Series 4 RX7 rotors and a lightweight RX8 eccentric shaft, were sent to Racing Beat in California. Racing Beat shaved material off the sides of the new rotors and balanced the entire assembly. The end product was a rotary engine that could scream effortlessly to 10,000rpm without losing balance or flow. To support the new mechanical limits of the engine both fuel and ignition systems were enhanced. KG Parts supplied the FPR, custom rail, lines and 1600cc secondary injectors while an HKS Twin Power ignition amplifier would spark the initial bang.

Speed1Allentown, aka KDR Performance, began the tear down and port polishiing – intake & exhaust – of the 13B rotary engine. Before the engine could be put back together, the entire rotating assembly, including a pair of new high compression Series 4 RX7 rotors and a lightweight RX8 eccentric shaft, were sent to Racing Beat in California. Racing Beat shaved material off the sides of the new rotors and balanced the entire assembly. The end product was a rotary engine that could scream effortlessly to 10,000rpm without losing balance or flow. To support the new mechanical limits of the engine both fuel and ignition systems were enhanced. KG Parts supplied the FPR, custom rail, lines and 1600cc secondary injectors while an HKS Twin Power ignition amplifier would spark the initial bang.

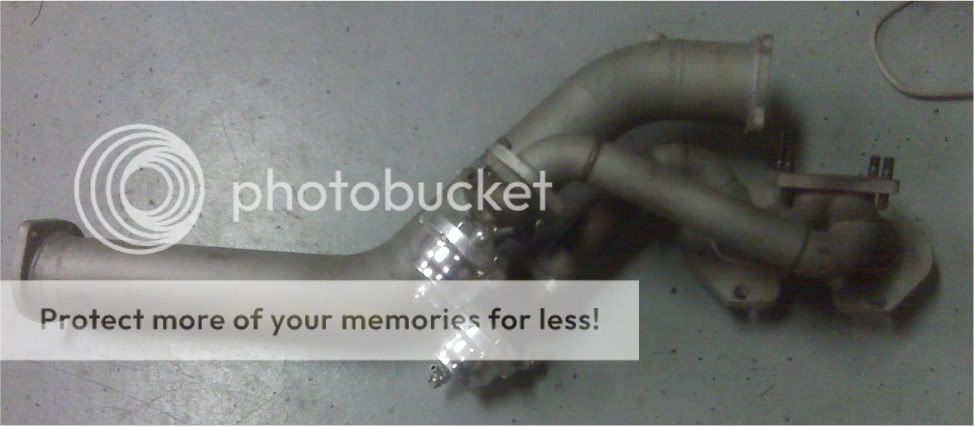

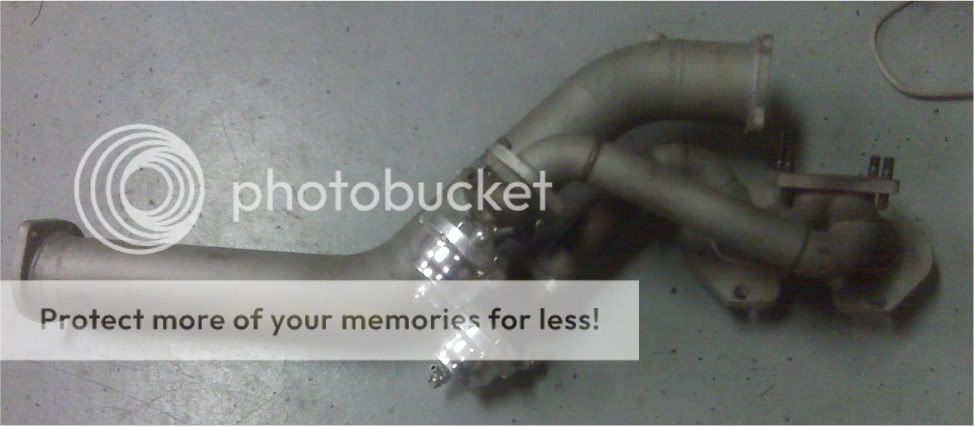

A blown motor has a funny way of taking things down with it. The upgraded HKS T04E turbo was one such bystander. Realizing this dangerously close to the first ProSolo of the season, I called fellow SSM competitor Andy McKee in desperation, hoping he was still selling his old turbo kit. Sure enough, it was sitting on his shelf, covered in cobwebs. Don't be fooled by the cobwebs, however, the turbo – a ball bearing Garret GT35R unit – had very light duty before Andy decide to try something else. An unmentionable shipping bill and Mr. McKee’s alacrity got the new turbo, tubular exhaust manifold, ceramic coated downpipe, and dual Tial wastegates to my door just in time for the New Jersey ProSolo. The setup was installed the next day and dyno tuned by Dave Barninger at Speed1. The car made nearly 400whp peak, but the biggest gains over the old setup were in the 3,000 to 5,000 rpm range. Here the ball bearing turbo shined, boosting both power and torque nearly 50 units. Thanks Andy!

A blown motor has a funny way of taking things down with it. The upgraded HKS T04E turbo was one such bystander. Realizing this dangerously close to the first ProSolo of the season, I called fellow SSM competitor Andy McKee in desperation, hoping he was still selling his old turbo kit. Sure enough, it was sitting on his shelf, covered in cobwebs. Don't be fooled by the cobwebs, however, the turbo – a ball bearing Garret GT35R unit – had very light duty before Andy decide to try something else. An unmentionable shipping bill and Mr. McKee’s alacrity got the new turbo, tubular exhaust manifold, ceramic coated downpipe, and dual Tial wastegates to my door just in time for the New Jersey ProSolo. The setup was installed the next day and dyno tuned by Dave Barninger at Speed1. The car made nearly 400whp peak, but the biggest gains over the old setup were in the 3,000 to 5,000 rpm range. Here the ball bearing turbo shined, boosting both power and torque nearly 50 units. Thanks Andy!

With fresh Hoosier A6 rubber slapped on the 18x10 CCW wheels, the car made it's appearance at the SCCA New Jersey Prosolo, but not without further drama. A last minute, parking lot repair of a damaged pulley almost left the car without power steering. Thanks to the support of fellow SSM competitor Jason Becker (commonly known as the nicest guy around) and his Pop, the car was repaired in time. Elena would be the first to shake down the car in Ladies 2 class. Competition in L2 is based on indexed time, making it difficult to outrun cars like the Kugler’s featherweight EP Honda CRX. Next, I finally got to experience the benefit of all the time, sweat and tears since the motor failed. The car held together and took the win in SSM by the second largest margin of any class at the race, earning “top qualifier” prize money, two tires from Hoosier, and $200 from Mazdaspeed. Not too shabby, just don’t compare the prizes to the cost of getting the car ready.

With fresh Hoosier A6 rubber slapped on the 18x10 CCW wheels, the car made it's appearance at the SCCA New Jersey Prosolo, but not without further drama. A last minute, parking lot repair of a damaged pulley almost left the car without power steering. Thanks to the support of fellow SSM competitor Jason Becker (commonly known as the nicest guy around) and his Pop, the car was repaired in time. Elena would be the first to shake down the car in Ladies 2 class. Competition in L2 is based on indexed time, making it difficult to outrun cars like the Kugler’s featherweight EP Honda CRX. Next, I finally got to experience the benefit of all the time, sweat and tears since the motor failed. The car held together and took the win in SSM by the second largest margin of any class at the race, earning “top qualifier” prize money, two tires from Hoosier, and $200 from Mazdaspeed. Not too shabby, just don’t compare the prizes to the cost of getting the car ready.

The next weekend the RX7 was back in action at Dover International Speedway for the SCCA Solo Dover National Tour event. After some competitor shuffling, SSM became stacked with the top cars & drivers from the 2010 SCCA Solo National Championships, including the BSP national championship Mitsubishi Evolution, the ASP national championship Corvette, and the podium finishing SM Nissan 240SX. In addition to the stiff competition, the course in Dover was exceptionally long and the climate was very hot. After my first run, which was an impossibly fast time right out of the hole, I nearly fainted idling back toward grid. The competitive pressure and heat were overwhelming, but the car itself may have been to blame for the lightheaded feeling of euphoria and adrenaline. Under full boost the car pulls nearly as many G’s longitudinally as it does laterally. That is no small feat considering the RX7 is arguably the best handling chassis ever manufactured and this particular example is rolling on twelve inch wide contact patches of Hoosier’s top of the line DOT approved race rubber.

The next weekend the RX7 was back in action at Dover International Speedway for the SCCA Solo Dover National Tour event. After some competitor shuffling, SSM became stacked with the top cars & drivers from the 2010 SCCA Solo National Championships, including the BSP national championship Mitsubishi Evolution, the ASP national championship Corvette, and the podium finishing SM Nissan 240SX. In addition to the stiff competition, the course in Dover was exceptionally long and the climate was very hot. After my first run, which was an impossibly fast time right out of the hole, I nearly fainted idling back toward grid. The competitive pressure and heat were overwhelming, but the car itself may have been to blame for the lightheaded feeling of euphoria and adrenaline. Under full boost the car pulls nearly as many G’s longitudinally as it does laterally. That is no small feat considering the RX7 is arguably the best handling chassis ever manufactured and this particular example is rolling on twelve inch wide contact patches of Hoosier’s top of the line DOT approved race rubber.

By the end of the weekend, the car finished on the podium behind the Nissan and the Corvette in open class. In SSM Ladies class, Elena was competing against more bumped up machinery, two CSP Miatas to be precise. The goal was to show the little Miatas who’s the big daddy in the Mazda family. Elena, now more familiar with the SSM RX7, was able to pull away from the roadsters by a substantial margin, bringing home the big win for the weekend.

Within a period of nine days the car had seen twenty-four national level autocross runs. Sure enough, the abuse caused a new failure. A drivetrain brace – known as the powerplant frame (PPF), which joins the rear differential with the transmission – had cracked in various places. The car needed a replacement PPF and a fabricator who could reinforce the unit to withstand the 400whp, R-compound shroud, drag-race launches. Back at Speed1, Dave Barninger sourced a takeoff PPF from a bastardized V8 swapped RX7 and reinforced the unit with quarter inch thick steel plates days before hauling out to the Oscoda Prosolo in Michigan, where the car was to face off against the RX7 of multi-time ProSolo Champion, Carter Thompson.

After the Oscoda ProSolo it became clear the car needed further improvements. The car finished more than a few tenths back from Carter Thompson’s monster RX7. With months before Nationals I naively thought there was sufficient time to upgrade and retune the suspension. Countless hours of research led me to Penske race shock builder extraordinaire Angelo Zarra of ANZE Suspension, in Long Island. ANZE worked with Joe Stimola assisting top-tier race teams custom engineer racing suspensions.

With Angelo’s help we selected a hybrid Penske 8100/7300 precision engineered coilover suspension. The front 8100 series are external reservoir double-adjustable monotube shocks. The rears adjust rebound only and have no reservoirs to install. The shocks used a clevis compatible upper mount for dynamic articulation. To mount the reservoirs ANZE provided their proprietary canister sleeves and brackets ensuring heat insulation and convenient bolt-on nature. After wrestling with spring lengths, spring rates, and shock body sizes, the suspension was complete.

The Penskes instantly provided superior feedback over the old Konis. The adjustability range was also drastically improved. Turning the knobs made big differences in the car’s behavior at speed! It was exciting but also presented many new challenges. I'd never really tuned such an adjustable shock. Trial and error was a big part of the learning process. For anyone testing and tuning similar set ups I recommend making one big shock adjustment at a time and comparing the driving characteristics.

The Penskes instantly provided superior feedback over the old Konis. The adjustability range was also drastically improved. Turning the knobs made big differences in the car’s behavior at speed! It was exciting but also presented many new challenges. I'd never really tuned such an adjustable shock. Trial and error was a big part of the learning process. For anyone testing and tuning similar set ups I recommend making one big shock adjustment at a time and comparing the driving characteristics.

In addition to the shock and spring improvements, the RX7 also received an upgrade from the OEM rear torsen limited slip differential to the formidable OSGiken 1.5 way Super Lock clutch type LSD. The new differential made the car feel much more composed under breaking since it allows the rear wheels to spin completely independently. And when throttle is applied, the diff locks fully, allowing for minimal wheel slip. This is especially helpful at corner exit. Speed1Allentown installed the rear diff with all new Mazda bearings, along with a new Tweak-It rear differential brace which provides more rigidity to the housing under continuous ProSolo drag launches.

In addition to the shock and spring improvements, the RX7 also received an upgrade from the OEM rear torsen limited slip differential to the formidable OSGiken 1.5 way Super Lock clutch type LSD. The new differential made the car feel much more composed under breaking since it allows the rear wheels to spin completely independently. And when throttle is applied, the diff locks fully, allowing for minimal wheel slip. This is especially helpful at corner exit. Speed1Allentown installed the rear diff with all new Mazda bearings, along with a new Tweak-It rear differential brace which provides more rigidity to the housing under continuous ProSolo drag launches.

The last piece of the puzzle was to bump up the rubber size once again. While the car felt amazingly responsive with rocket-like gearing sitting on 285mm rear tires, jealously struck over the success of the extraordinarily super-wide-tire’d, top performers like Carter Thompson and Mike Johnson. CCW provided properly sized rear wheels and a borrowed fender roller made mounting the monstrous 315/30/18 Hoosier A6s feasible. Clearances were tight at the rear trailing arm, so we installed aftermarket arms and offset the mount at the sub-frame.

After all was said and done, what was created, in theory, was a car completely capable for the task at hand… a National Championship. However, at this point, months of our time cushion had elapsed and Nationals was only weeks away. Due to other commitments and very uncooperative weather, testing the new wheel/tire/spring setup before Nationals was not possible.

We loaded up and proceeded on the endless drive to corn country in a borrowed Chevy Suburban (Thanks Sandro!) with the Mazda traveling in luxury on a trailer – rather than the typical protocol of tires dangling out the back of the hatchback, held in by bungee cords. Anxiety ridden throughout the entire trip since I didn’t know what to expect of the new setup, I tried to calm my nerves with endless stops for coffee and Redbull.

Nationals Update to Follow…

By: Jake

By: Jake